Australia’s forest management practices are among some of the best in the world. Based on a combination of meeting sustainable timber yields while maintaining and protecting the environmental, social and economic values of the forests; Australia’s approach to forestry ensures that local timber species thrive, harvested timber is replaced and as much of each tree is processed for wood products.

When trees are harvested and used for timber, not all parts of the tree are equal. There are many different qualities that can come from an individual tree, which all have different uses and by-products. It is responsible to use as much of any harvested tree as possible. At ASH, the logs we receive are third party verified as meeting Australian Standards and PEFC certification. Our efficient processes and optimal design of products means that we are able to use the entirety of every log we receive. This process allows us to minimise waste, contribute to one of the world’s best circular economies and store as much carbon for life as possible! This blog will run through the harvesting process, how each log is used at ASH and the benefits of sustainable forestry. So, if you’re interested, read on!

Timber harvesting is a forest management practice that requires careful planning and strict instruction to ensure a quality outcome. Trees are harvested by experienced contractors and professional foresters in accordance to a coupe plan designed specifically for that area of forest. The careful execution of these operations ensures that important areas for conservation, habitat retention, access and other important factors are monitored and protected before, during and after the harvesting process.

Throughout each coupe, the trees to be removed are marked in the process of selective cutting. The selected trees are then felled, processed and transported from the coupe to a storage site or central processing yard. Once each tree has gone through the process of topping, delimbing, bucking and debarking they are then graded and sorted into sizes before being transported to a sawmill or timber manufacturing facility where the remaining work is completed.

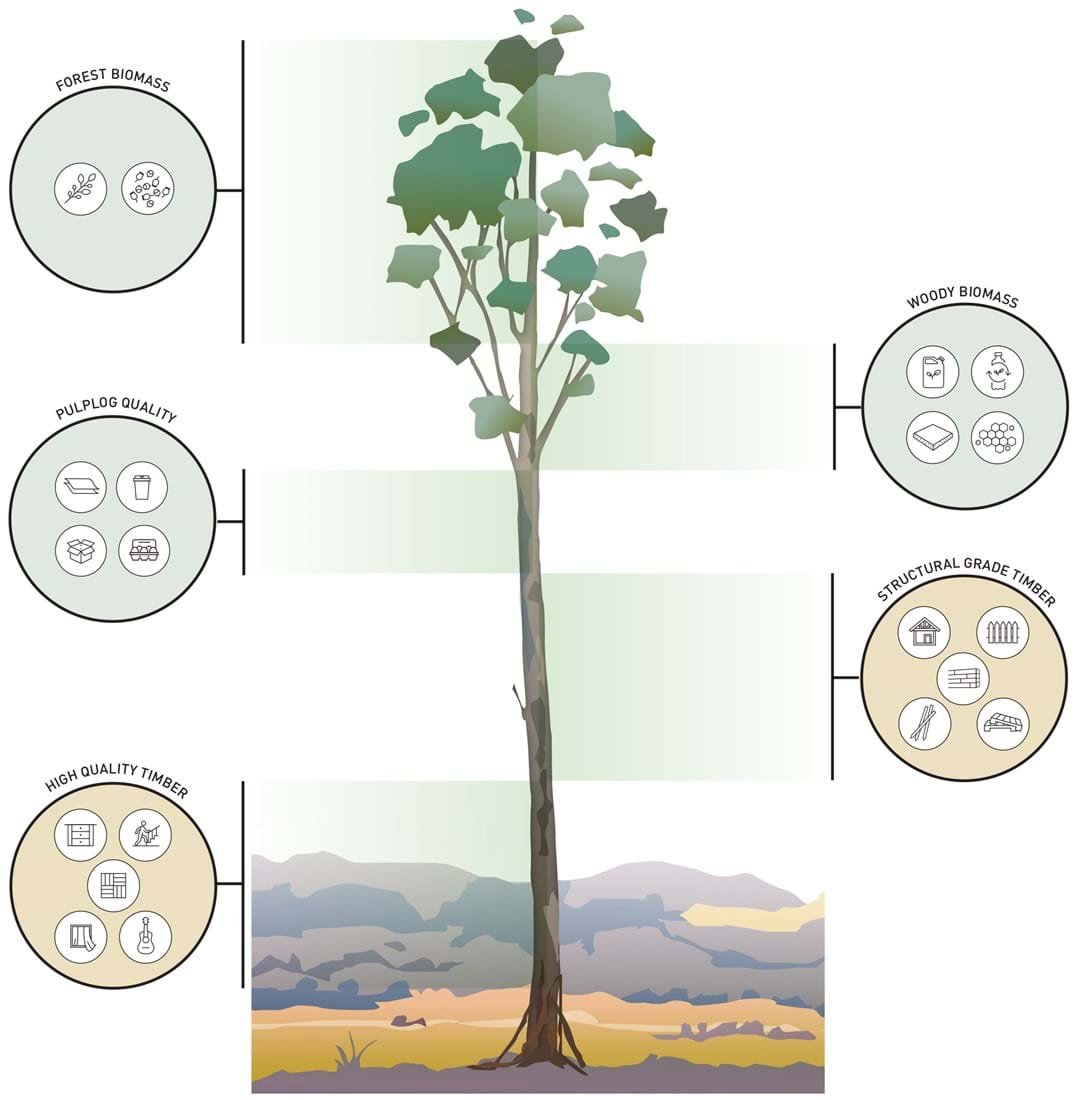

Not all parts of a tree are equal, a variety of different qualities of timber can come from an individual tree. Each tree is graded into sections that can indicate what each part can be used for. This includes:

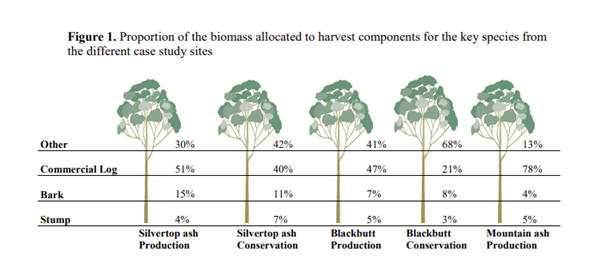

At ASH, one of the species we process is Mountain ash, which is included in our GoodWood Victorian ash and Tasmanian Oak ranges. Unlike other species, approximately 78% of a Mountain ash tree can be used as a commercial log which is used to make the majority of wood products we see in our day to day lives. The high recovery rate means that only a small percentage of each Mountain ash tree is processed as pulplog, woody biomass and forest biomass.

Image Source: Forest & Wood Products Australia

Image Source: Forest & Wood Products Australia

We pride ourselves on ensuring each log we receive is processed into its highest value application.

By eliminating waste and maximising value through the design of products and processes, ASH have been able to contribute to a circular economy. These processes counteract the typical make, use and dispose cycle in favour of re-using and recycling wherever possible. With 100% of every log received being used and ensuring that there is no wastage, we are able to contribute to one of the best circular economies in Australia. Learn more about the Timber Industry’s Circular Economy here.

Timber is one of the only renewable building materials, which is why it is widely known as The Ultimate Renewable. Growing trees absorb carbon dioxide from the atmosphere, storing that carbon in its wood, leaves and other organic matter. When wood from trees is used for production, the carbon is stored for life in that product, and is only released if the wood is burned or rots. Wood products have a long service life, for example, when used for house framing the carbon storage life is around 100 years; 30 years in furniture; 30 years in railroad ties and approximately 6 years in pallets and paper. Once the wood has reached the end of its lifecycle it can be recycled and reclaimed, which is also an increasingly popular design requirement. What’s even better is that up to 50% of the dry weight of wood is made up of carbon so a timber framed home can store around 7.5 tonnes of carbon.

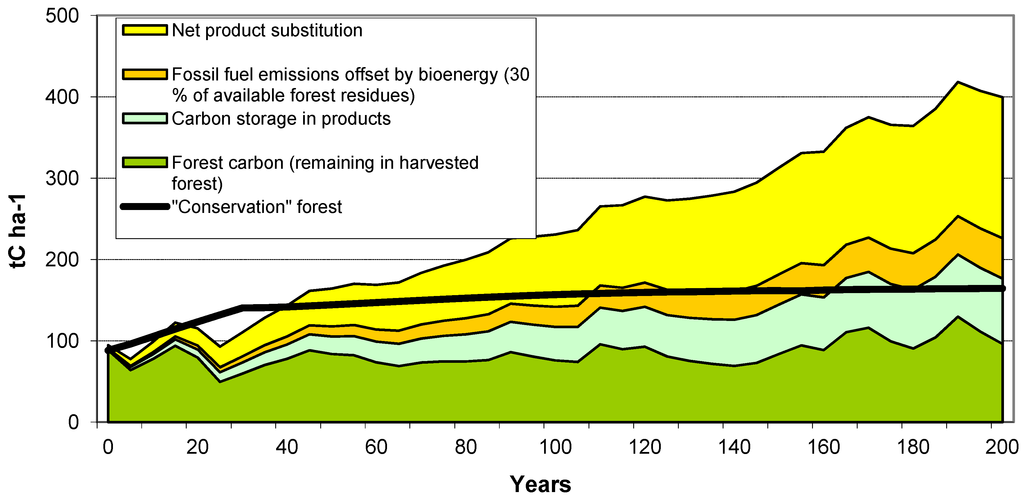

The graph below compares the estimated greenhouse gas balance of two key managed regrowth forest areas that are managed for production against the option of managing these forests for conservation only. Once a tree has reached the upper end of its growth curve, its benefit to carbon mitigation slows down. It’s ability to store carbon reduces, highlighting that harvesting trees at an optimum age and replanting new ones in their place plays a significant part in climate change mitigation. Although conservation forests play a role for biodiversity, comparatively, they are not as effective at storing carbon even when assuming that there are no bushfires. Forests managed for production provide the greatest ongoing greenhouse gas benefits with the long-term storage of carbon in products, the circular life cycle of harvested wood products and the substitution benefit of using wood products compared to more greenhouse gas intensive options.

Image Source: Greenhouse Gas Balance of Native Forests in New South Wales, Australia

Image Source: Greenhouse Gas Balance of Native Forests in New South Wales, Australia

As you can see, there are many uses for each harvested tree and here at ASH each log is used for its maximum application, while the remainder of the log is used for paper, packaging, animal bedding and green energy. Supporting the Australian forestry industry and wood products ensures that we can continue to enjoy the beauty of natural products while keeping the cycle of capturing carbon in timber continuing.

"*" indicates required fields