MASSLAM is a glue-laminated (GLT) mass engineered timber solution from Australian Sustainable Hardwoods (ASH). Accelerating the use of mass timber in Australia is a known pathway to significantly assist with decarbonising the construction sector and contribute to Australia’s goal of achieving net zero by 2050. Additional benefits including construction speed, sustainability and occupant well-being solidify MASSLAM as the modern construction choice for architects, specifiers and builders alike.

MASSLAM utilises uniquely attractive Australian timbers like Australian Oak (Tasmanian Oak) and Plantation Oak, chosen because they have some of the best strength-to-weight ratios of any timber species worldwide. ASH’s glulam timber systems (including columns, beams, and floors) are manufactured at our Australian-owned timber plant in Heyfield, Victoria.

Our mass timber solutions are designed and manufactured for assembly by our highly-skilled team of MASSLAM designers and engineers and are intended for large domestic and commercial structures. The skill and experience provided by our in-house MASSLAM team is unmatched. Experience the consistency and ease of dealing with the same project manager from conception through to completion.

Solidifying our position at the forefront of mass timber design and manufacture in Australia, ASH have three state of the art robotic CNC machines providing enhanced processing capacity that allows longer spans, higher ceilings, increased floor space and lesser beam depth. Better still, mass timber provides unbeatable cost and time efficiencies when compared to conventional construction materials like concrete and steel.

ASH’s MASSLAM is the only mass timber glulam in Australia to hold Engineered Wood Products Association of Australia (EWPAA) certification.

All this equates to ASH being industry-leaders and providing the best mass timber system in Australia.

MASSLAM 45 is ASH’s brand of glue laminated (GLT) mass timber systems including columns, beams and floors.

Manufactured specifically for large-scale commercial construction projects. MASSLAM 45 uses Australian Oak due to the high strength-to-weight ratios compared to timbers worldwide. The only glue-laminated timber in Australia to hold EWPAA certification.

Suitable applications:

These samples are cross sections of a typical mass timber column or beam, intended to provide an accurate representation of the appearance and scale of these elements. As such, they are substantial in size and weight, and generally reserved for architects and building firms working on commercial, large-scale developments. If you are looking for structural timber (traditional F17 or laminated and finger-jointed SUPALAM F17 for an architectural look, please select the Australian Oak Uncoated sample.

Currently out of stock – sample requests will be placed on back order and shipped from approx end-March.

MASSLAM 38 is ASH’s brand of glue laminated (GLT) mass timber systems including columns, beams and floors.

Manufactured predominately for large-scale domestic and commercial construction projects. MASSLAM 38 uses Plantation Oak due to their high strength-to-weight ratios compared to timbers worldwide. The only glue-laminated timber in Australia to hold EWPAA certification.

Suitable applications:

These samples are cross sections of a typical mass timber column or beam, intended to provide an accurate representation of the appearance and scale of these elements. As such, they are substantial in size and weight, and generally reserved for architects and building firms working on commercial, large-scale developments. If you are looking for structural timber (traditional F17 or laminated and finger-jointed SUPALAM F17 for an architectural look, please select the Australian Oak Uncoated sample.

Calculate the sequestered CO2 equivalent of your project and the time it takes to regrow the timber.

Timber is one of the few building materials with the ability to create a closed loop, circular economy. The very existence of sustainable timber production helps reverse anthropogenic climate change.

Population growth and urban sprawl across major centres around the globe is placing increased pressure on the need for housing and infrastructure; demanding an ever-increasing appetite for resource and finite materials. Traditional construction is responsible for anywhere up to 50% of the world’s CO2 emissions through embodied energy. In a sustainability conscious world, the construction industry is diverting its focus toward reducing the impact on waste and climate change. As our cities increase in size and height, our thirst for robust materials will continue to grow. As a result, a disconnect with nature and associated psychological impacts will intensify. Thanks to technological advances and continuous improvement in manufacturing, one material has emerged with the opportunity to reverse this trend and is gaining international recognition as the solution to our modern day needs: mass-timber construction. MASSLAM utilises massive sections of glue laminated timber in structural applications – replacing finite materials such as concrete and steel.

Having significantly lower embodied energy to produce a solution, combined with CO2 sequestration during growth, mass-timber is truly ‘better than carbon neutral’. The amount of CO2 stored within one cubic metre of MASSLAM after embodied energy is deducted equals approximately 673kg. A 1,000 cubic metre project will store 673 tonnes of CO2 and can be regrown in as little as 5 minutes in Victorian forests. Sustainable forest certification ensures the forests are responsibly managed in perpetuity and with fewer lasting environmental impacts, the construction industry can now be the answer. Better still, MASSLAM used in visual applications doesn’t just look great but adds to biophilia in the built environment – helping humans feel more connected to nature and subsequently creating happier workplaces, increasing productivity and lowering stress.

According to detailed studies by WoodSolutions, commercial structures built with mass timber offer cost savings over concrete and steel. Speak to your MASSLAM specialist for the detailed report.

Consistently installing faster than traditional construction, recent mass timber case studies comparing multiple projects in Australia have shown up to 30% faster construction times. Much of this can be attributed to early services rough-in and assembly. This speed and efficiency comes from the fact that mass timber is lighter, easier, safer to handle and install than concrete and steel. Speed of construction is a substantial consideration in cost assessment due to time related expenses such as crane and other plant hire; wages for on-site workforce; insurance premiums; permits and certifications. The reduced program offered by timber structures can also enable time critical projects to be realised. This can be a crucial consideration for many projects, including schools and student accommodation buildings, for which funding periods can be set and term dates fixed.

The constructibility of mass-timber buildings are safer in general. Tier 1 builders are reported as stating many projects show no Lost Time Injuries. Part of the reason for this is the elimination of on-site risks with prefabrication. Prefabricating or pre-attaching connectors in an automated assembly off-site before delivery reduces the need for working at heights as well as the time required to assemble. Smaller and easier hand tools are utilised, as are smaller crews. Additionally, there is less need for welding or hot works, easier anchoring of safety harnesses, the ability to pre assemble safety barriers and eliminate live-edges before craning.

All MASSLAM members uniquely pass through the world’s largest four-side planer to ensure clean surface and squareness before machining. ASH’s Hundegger (CNC) then machines to within +/-1mm accuracy to the parameters drawn out in earlier 3D design model. With the ability to efficiently and automatically process up to 1,300 x 450mm end sections, MASSLAM does not need to be block laminated. Block laminating requires two halves (or more) to be CNC profiled and then joined together – often creating misalignment of profiles and negating the millimetre accuracy of the CNC or four-side planer. ASH’s process eliminates this risk. Given some MASSLAM products are ~40% stronger than international mass-timber, we can negate the need to design with members thicker than 450mm or to block laminate. Comparatively, concrete and steel tolerances can be +/-15mm. The benefits of accuracy in MASSLAM are far and wide but can be critical for air tightness, installation, energy efficiency, constructability and overall building performance.

MASSLAM is 18% the weight of concrete and 80% the weight of steel for the same structural requirement. This means there is less need for expensive foundations. It also means more material can reach site with fewer deliveries. Lifting is quicker and can be done with smaller cranes. Less noise, dust, vibrations and truck movements result in less disruption of neighbourhoods and existing activities or tenants.

Mass timber buildings can be safer than traditional builds under fire, particularly when related to sprinklered buildings. Large sections of timber are very hard to burn. Imagine trying to start a campfire with a large log!?! (You can’t). Even under extreme fire, MASSLAM has calculable performance and maintains structural integrity. As MASSLAM is exposed to fire, a level of char is created on the fire-affected surface while maintaining structural strength behind this ‘char layer’. The structural strength is directly proportionate to the unaffected wood. Concrete with steel connections can buckle under the same heat.

MASSLAM is independently fire tested under load and for char against AS1530.4 for up to 120 minutes. With the char rate being predictable and known, designing for fire to meet the code can be as simple as adding a sacrificial char layer equivalent to the FRL requirements. For example, if a 300mm x 300mm MASSLAM 45 column in a commercial building is required to achieve a FRL of 60min, the column could be supplied in one of the following options:

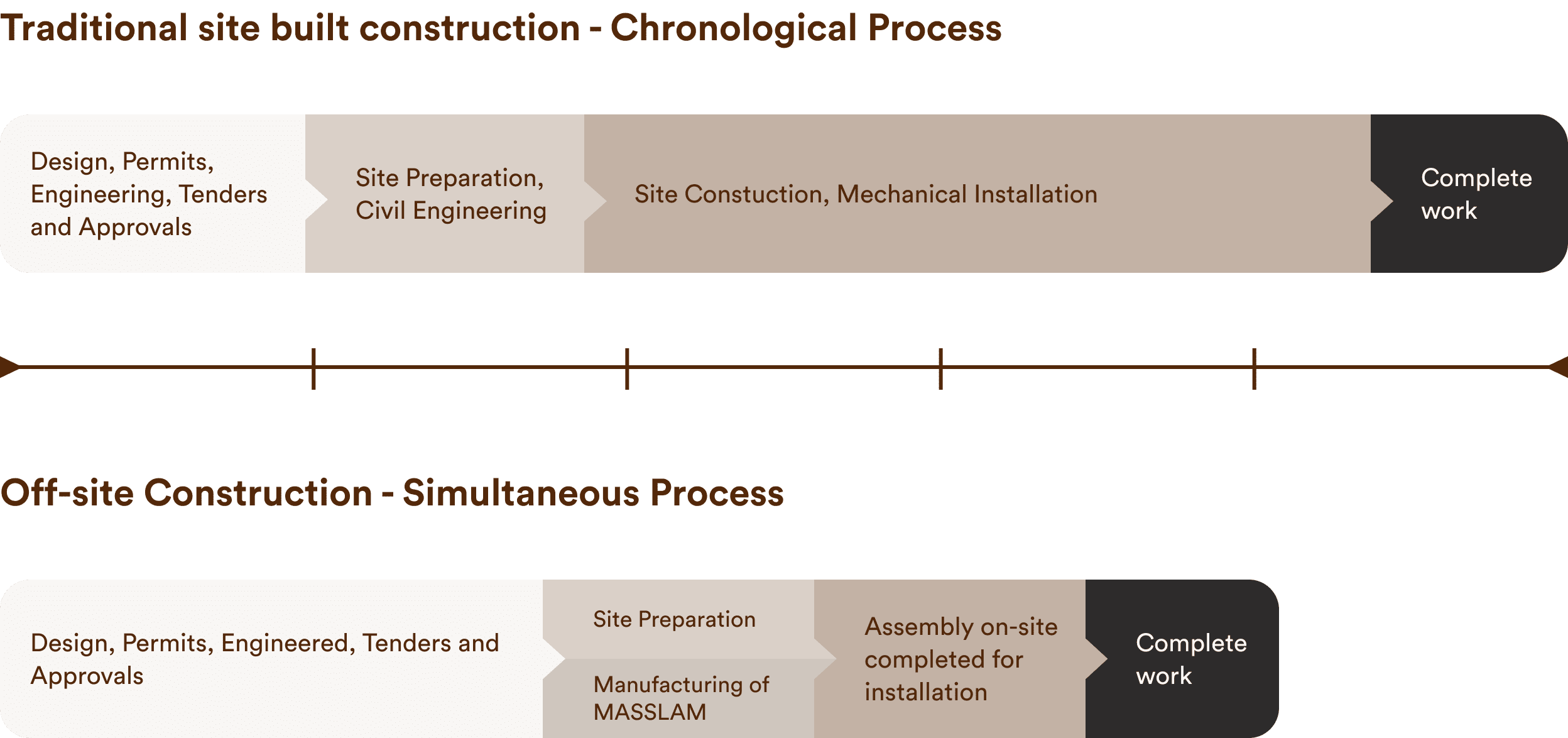

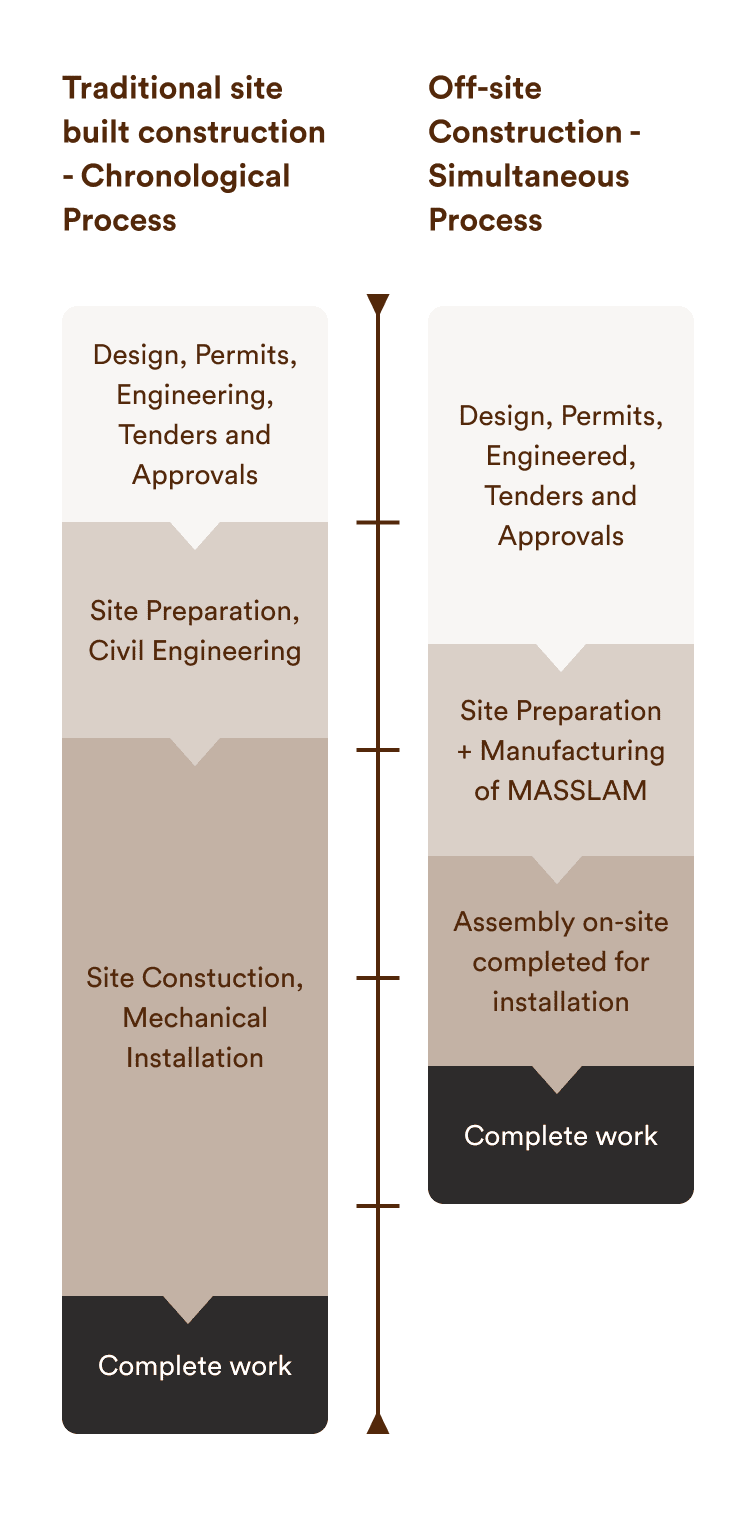

Design for Manufacture & Assembly (DfMA) is a type of design process that considers the manufacture and assembly of building components for optimal speed, safety and quality of a build. Prefabrication and off-site assembly will benefit a build but requires a complete change in thinking. Design teams are required to put in more work up front so that the desired prefabrication and assembly efficiencies can be realised. Buildings cannot be partially designed before fabrication – prefabrication of each element is governed by the digital 3D design model. The building must be considered 100% complete before processing. There can be no change of design once manufacturing has commenced. An example of the benefits of DfMA is shown below.

The process begins with your concepts or plans where ASH offer a free schematic design service or a basic ‘reverse engineered’ guide of various products to narrow in on the ultimate outcome for the clients’ needs. Once the MASSLAM products and system are selected, the engineering team create a digital 3D model detailing all of the chosen components with intricate details including connection types, sizes, screws, CNC requirements and the exact locations of every detail. Potential issues with the plans can be addressed during this detailed 3D model by the engineering team – rather than being fixed on site by an expensive labour force or holding up the critical path.

Once the client signs off on the 3D model the structure is considered ‘effectively built’ and cannot be altered. This information feeds the MASSLAM automated production and CNC line where coatings, attaching of connectors and labelling of each member ensures superior on-site installation efficiencies. ASH store the finished goods and can even deliver in order of lifting sequence (subject to prior approval).

Get in early. Do not design too far down the path before talking with your MASSLAM specialist. MASSLAM is available in uniquely high strength materials that can offer:

All construction materials require unique consideration of their strength and weakness in order to maximise cost efficiency. MASSLAM can be the most cost effective of all systems but this may not be the case if you design for concrete or imported mass timber and hope to compare price. It is for these reasons why it is imperative to get your MASSLAM specialist in early. See Design and Construction chain below.

Client

Architect

Approving Authorities

Architect

Structural Engineer

MASSLAM Specialist

Project Manager

Architect

Cost Planner

MASSLAM Specialist

Project Manager

Architect

Structural Engineer

MASSLAM Specialist

Project Manager

Specialist Consultants: Acoustic, Hydrautic, Fire, Facade, etc.

Architect

Cost Planner

MASSLAM Specialist

Project Manager

MASSLAM Specialist

Project Manager

MASSLAM Specialist

Project Manager

Client

Architect

Approving Authorities

Architect

Structural Engineer

MASSLAM Specialist

Project Manager

Architect

Cost Planner

MASSLAM Specialist

Project Manager

Architect

Structural Engineer

MASSLAM Specialist

Project Manager

Specialist Consultants: Acoustic, Hydrautic, Fire, Facade, etc.

Architect

Cost Planner

MASSLAM Specialist

Project Manager

MASSLAM Specialist

Project Manager

MASSLAM Specialist

Project Manager

Initial (free) discussions with the MASSLAM team.

Project specifics incorporated.

Preliminary sizes/species/connections/costings determined.

Completed Design used to create shop drawings and CNC files.

Building is considered ‘complete’ from a design perspective.

Shop drawings determine prefabrication process.

Chosen species used as feedstock to create glue laminated components.

Each species has its own unique strength and appearance.

Robotic CNC profiling performed on each member per design and fixing requirement.

Largest mass timber CNC in the world.

Connections are coordinated, fabricated and pre-attached where relevant.

A factory coat/primer or moisture permeable wrap is applied to mitigate risk from weather during construction.

Components are completed and stored until requirement.

Deliveries can be performed in order of lifting sequence to greatly increase on-site productivity.

| LABEL | MASSLAM 38 | MASSLAM 45 |

|---|---|---|

| Equivalent GL15 | Equivalent GL17 | |

| Species | Plantation Oak | Australian Oak (Tasmanian Oak) |

| Bending Strength | F’b = 38MPa | F’b = 45MPa |

| Tension Strength | F’t = 19MPa (parallel)

F’tp = 0.5MPa (perpendicular) |

F’t = 25MPa (parallel)

F’tp = 0.6MPa (perpendicular) |

| Shear Strength | F’s = 5.0Mpa | F’s = 5.0MPa |

| Compression Strength | F’c = 38MPa (parallel)

F’cp = 10MPa (perpendicular) |

F’c = 45MPa (parallel)

F’cp = 10MPa (perpendicular) |

| Bearing Strength | F’l = 45MPa (parallel)

F’p = 10MPa (perpendicular) |

F’l – 59MPa (parallel)

F’p = 10MPa (perpendicular) |

| Modulus of Elasticity | E = 14,500MPa

E0.05 = 10,875MPa E90,mean = **960MPa |

E= 16,700MPa

E0.05 = 12,525MPa E90,mean = **1,110MPa |

| Modulus of Rigidity | G = 960MPa | G= 1,110MPa |

| Joint Group | JD4 | JD3 |

| Design Density | Mean = 600kg/m3

Pk = 500kg/m3 |

Mean = 650kg/m3

Pk = 545kg/m3 |

| Service Class | 1 & 2 only if untreated (3 in H3 treated with limitations) | 1 & 2 only if untreated (3 in H3 treated with limitations) |

| Adhesive | Externally rated, high temperature PUR | Externally rated, high temperature PUR |

| Formaldehyde Emissions | None (E-0) | None (E-0) |

| Certification | PEFC & RW | PEFC & RW |

| Char rate | *0.68mm per min | *0.59mm per min |

| Movement in Service -Axial | 0.02% per 1% change in MC | 0.02% per 1% change in MC |

| Movement in Service – Radial | 0.20% per 1% change in MC | 0.20% per1% change in MC |

| Movement in Service – Tangent | 0.31% per 1% change in MC | 0.31% per 1% change in MC |

| LABEL | MASSLAM 38 | MASSLAM 45 |

|---|---|---|

| Machine finish | ≡ 60 grit | ≡ 60 grit |

| Machine tolerance | As per AS2796 | As per AS2796 |

| Grain structure of feedstock | Back sawn | Quarter sawn for stability |

| Gum Vein – Tight | No limit | No limit |

| Gum Vein – Loose | No limit | No limit |

| Gum Pockets | No greater than 7mm wide and 4mm deep | No greater than 7mm wide and 4mm deep |

| Sound Knots/Burls | No Limit | No limit |

| Loose Knots | filled | Nil |

| Pinhole | No limit | No limit |

| Hobnail | No limit | No limit |

| Black Speck | No limit | No limit |

| Rot/Decay | Nil | Nil |

| Heartwood | Nil | Nil |

| Checking | No limit | No limit |

The MASSLAM line operates the largest and most efficient glulam CNC in the world with precision accuracy. This machine can process end sections up to 1,300 x 450mm with millimetre accuracy in one automated pass. The Hundegger K2i has over 160 tools and 6-axis machining. Tools available include saws, chain saws, routers and drills – to name a few. Tools chosen for use are determined by the 3D model and construction requirements.

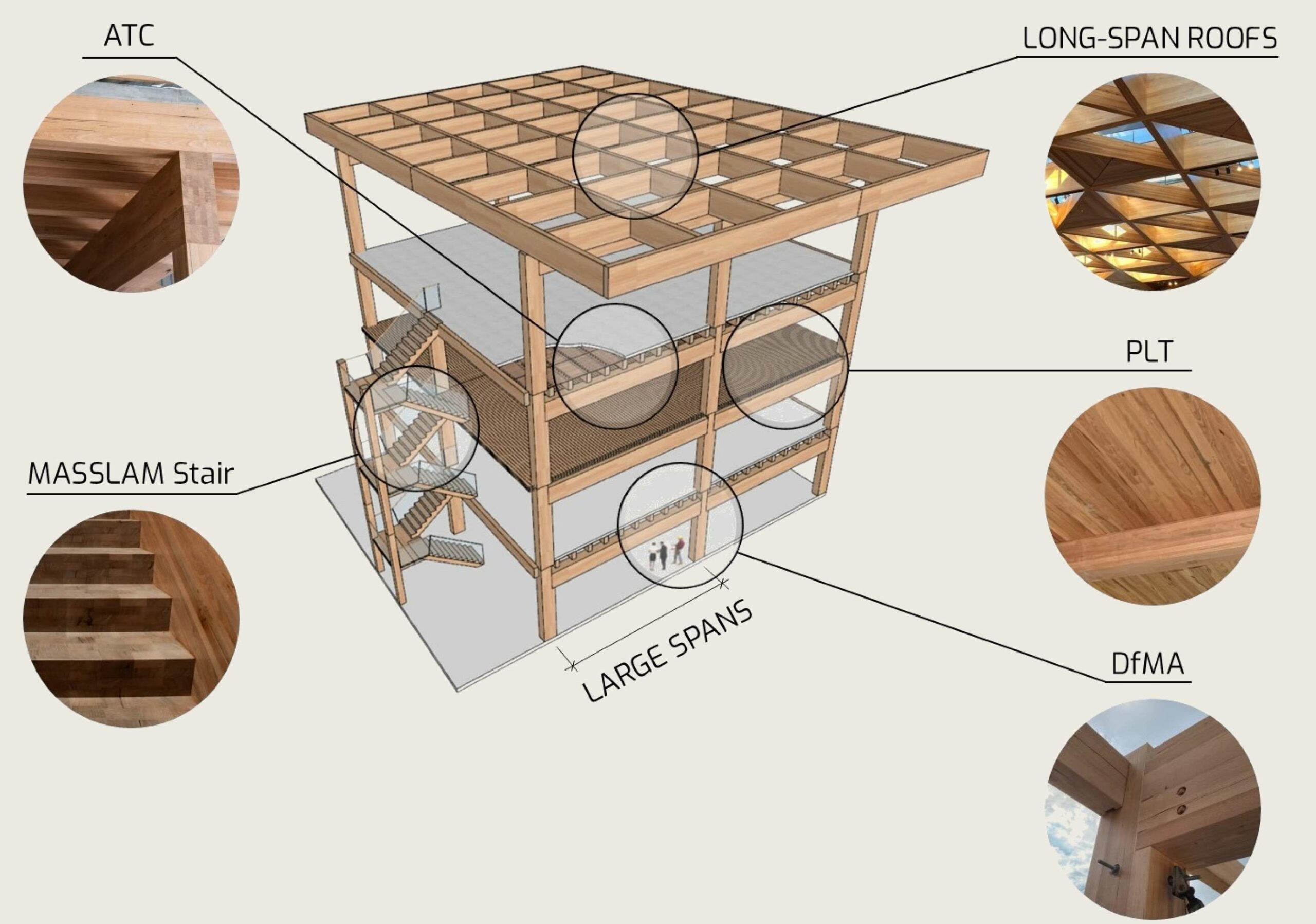

Prefabricated floor assembly, our Advanced Timber Composite Floors (ATC) are ASH’s mass timber flooring solution. ATC provides a DtS pathway for fire which allows you to visually express the soffit – all while spanning further with less resource and at a more competitive rate.

ATC can often be known as TCC (Timber Concrete Composites). These systems are efficient in the construction of modern multi-storey mass timber buildings because of their higher strength and stiffness-to-weight ratios, larger span-to-total depth ratios, higher in-plane rigidity, and acoustic, thermal, and fire performances when compared with the conventional timber-only system (Ceccotti, 2002; Dias et al., 2016, 2018; Yeoh, Fragiacomo, De Franceschi & Heng Boon, 2011).

CNC Machining makes for efficient and attractive profiling of members but they also cater to an infinite number of connection possibilities. These include concealed dovetail connections, birdsmouth connections, steel plates, mortise and tenon joints pilot screw holes, char plugs and processing for all proprietary connection types. Talk to your MASSLAM specialist about preferred connection types specific to your project objectives.

MASSLAM members can be coated or stained to meet the design intent. Critically, coating is required to protect members from damage due to variations in humidity or exposure to UV and weather. The MASSLAM line is equipped with a coating line or moisture permeable wrapping to allow members be delivered with at least one protective option before delivery. Final coats are required after installation for adequate protection.

For more detail, see the MASSLAM Design Guide and MASSLAM Coating Guide.

Advanced Timber Composite Floors (ATC) are ASH’s mass timber flooring solution. ATC provides an aesthetically pleasing validated performance pathway for fire which allows you to visually express the soffit – all while spanning further with less resource and at a more competitive rate than Cross Laminated Timber (CLT).

ATC is arguably the most attractive mass timber flooring solution and tested to comply with Australia’s strict fire and acoustic requirements. ATC is a hybrid flooring system utlising MASSLAM, shear connections and a reenforced concrete screed to create an unbeatable composite floor which utilises each material’s strength in a complimentary way.

ASH’s first ATC floor system is a TCC (Timber Concrete Composite) using our MASSLAM beams. These systems are efficient in the construction of modern multi-storey mass timber buildings because of their higher strength and stiffness-to-weight ratios, larger span-to-total depth ratios, higher in-plane rigidity, and acoustic, thermal, and fire performances when compared with the conventional timber-only system (Ceccotti, 2002; Dias et al., 2016, 2018; Yeoh, Fragiacomo, De Franceschi & Heng Boon, 2011).

At ASH we are constantly looking to develop our capabilities and innovate such that we can supply the market with high quality solutions that help drive the industry forward. As ASH’s ATC range develops, not all of the solutions will be TCC.

ASH have undertaken >$750k worth of research and Development in preparing ATC for market. Tests include:

Mass timber is made up of laminated layers of solid wood that are used to make a strong, sustainable, fire and acoustic resisting building material that can be used in commercial and domestic structures. Our GLT MASSLAM range is a high-quality building material that will be manufactured to project specifications by our expert engineering and production team.

Mass timber can be used in applications such as:

a. Columns

b. Beams

c. Timber/Concrete Composite (ATC) floors

d. Laminated Timber Panels (LTP)

e. Stairs

| Width (mm) | Can be used with any | Depth (mm) | |||

|---|---|---|---|---|---|

| 120 | x | 200 | 270 | 350 | 420 |

| 165 | 270 | 370 | 470 | 570 | |

| 205 | 335 | 460 | 590 | 710 | |

| 250 | 410 | 560 | 710 | 860 | |

| 290 | 480 | 660 | 830 | 1000 | |

| 335 | 550 | 750 | 950 | 1150 | |

| 380 | 620 | 840 | 1070 | 1290* | |

| 420 | 690 | 940 | 1190 | ||

| 450 | 760 | 1030 | 1250 | ||

| 830 | 1220 | ||||

| 900 | 1300* | ||||

| 970 | |||||

| 1040 | |||||

| 1110 | |||||

| 1180 | |||||

| 1250 | |||||

| 1300* | |||||

Answers to some of our most frequently asked questions about MASSLAM timber.

Regardless of species used and the natural durability class or any Hazard Class treatment employed, it is not recommended that any GLT, Glulam, CLT or mass timber be used in full weather (Service Class 3). To use in external environments – design, detailing and protection measures need to be employed so that any member conforms to a weather exposure level of Service Class 2 or less. For detailed explanations, read the MASSLAM Design Guide or this blog on Service Classes.

An ‘apples for apples’ comparison needs to be considered. For example, an office structure with visually expressed columns, beams and soffit in mass timber would be comparable to a concrete structure + the architectural joinery used to meet the architectural intent. Similarly there are reduced foundations, deliveries and overheads due to the speed of installation, safety and reduced weight achieved in mass timber. When considered holistically, mass timber can be significantly more

cost effective. Talk to the mass timber team to ensure design considers cost efficiency.

The timbers used in our MASSLAM mass timber range include GoodWood Victorian ash and Tasmanian Oak, Radiata Pine, and Plantation Oak. This provides a wide range of strength and appearance options for any mass timber project.

All coating types (to our knowledge) are suitable on MASSLAM although which coating is best for your application will depend on the application of use, design intent, sustainability or longevity requirements, risk areas, desired maintenance regime, etc. To learn which coating might be best for your project, read the MASSLAM Coatings guide.

ASH recommend and offer a one-way, vapour permeable plastic wrap as a temporary weather protection solution to best protect each member from the impacts of weather exposure before the members are fully protected in their intended application. Throughout years of tests and experience, the temporary wrap has shown to have the best protection when compared against all other known temporary weather protection measures investigated – including pre-coating. While most projects are supplied with a pre-coat by ASH, our experience and preference is that the vapour permeable wrap is best.

Mass timber is priced based on the specific requirement of material volume + CNC time + bracketry and fasteners. While a basic $m3 rate can be provided by the MASSLAM team, it’s more accurate to be specific about your needs. Talk to one of the MASSLAM team to provide a quality estimate.

It is a clear treatment. We use the Tru-Core H3 Azole treatment – otherwise sold as IronAsh.

Wraptite SA is a one-way, vapour permeable, self adhesive membrane which comes standard on all MASSLAM end grain. This limits weather checks or movement-in-service related issues in the ends of all members.

Yes – to ensure your mass timber is sustainable, make sure you source it from third party verified sources such as those with accreditation to PEFC, Responsible Wood (RW) or FSC.

CLT, or Cross Laminated Timber, is a mass timber panel where each layer is glued at 90 degree orientation to the layers adjacent. CLT is typically used for floors in post and beam construction (in conjunction with MASSLAM or GLT) and/or in load bearing walls and floors in residential structures. ASH do not supply cross laminated timber panels however do offer panelised solutions such as Advanced Timber Composites (ATC) for floors and/or load bearing columns in place of walls.

If ASH have your project booked into the production schedule, ASH can guarantee the timber. Thanks to building sustainability schemes, climate objectives and human desires for natural materials, demand on certified timber is increasing year on year – in all categories and in most parts of the world. ASH are no different. However, ASH are uniquely in control of supply from log to finished product. If ASH have an agreement to supply your mass timber project, it will be delivered on time.

The following are maximum production sizes. Longer, wider, thicker can be achieved through engineered solutions (talk to the MASSLAM design team for more). Length: 12m. Depth = 1,300mm. Width = 450mm. In a high strength product such as MASSLAM 45, a maximum column size of 1,300mm x 450 can be the equivalent strength of a European Spruce 1,300 x 900mm.

A MASSLAM specialist is someone from our extensive in-house engineer and design team. ASH has a wide range of experts ranging from structural engineering to logistics so we can have better control of project solutions by supplying our own feedstock, automated manufacturing capability, skilled finishing and packaging, and delivery to site. This means that our design team work with project stakeholders and closely with our inhouse production team so that we can provide consistent information for manufacture.

Learn about the importance of your purchasing power when it comes to mass timber products, why it is imperative to select local over imported and what steps you can take to do so.

ASH can guarantee your mass timber project will be delivered on time if we have your project booked for production.

"*" indicates required fields