The Boot Factory featuring MASSLAM has been crowned Best Timber Building at the 2025 Australian Timber Design Awards, standing out among Australian’s most innovative timber projects.

The restoration project also claimed the award for Excellence in Timber Design (Public Building), underscoring the power of locally sourced hardwood to transform heritage architecture.

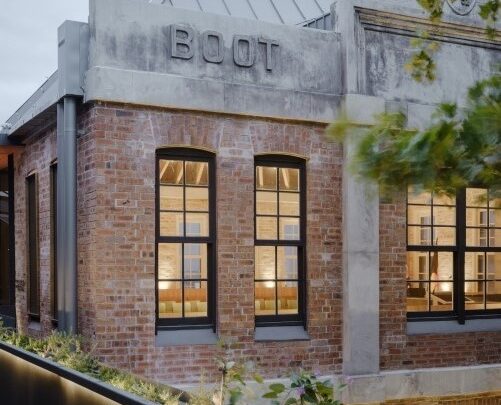

Originally built in 1892, and the last remaining Victorian-era industrial building in Bondi Junction, the Boot Factory was transformed through an innovative restoration by Archer Office and Schiavello Construction.

As the name suggests, the factory was once home to boot manufacturer Sidaway & Son. By 1969, manufacturing ceased and the building became home to various community services and local organisations. In 1984, Waverley Council acquired the building, but due to structural concerns it was left vacant from 2007 and faced demolition.

Thanks to passionate community advocacy, Council engaged Archer Office to explore options to save the building. And save it they did.

While the building’s original brickwork exterior was carefully retained and original structural timber was used to create new front doors, the internal structure and roof were entirely rebuilt using mass timber supplied by Australian Sustainable Hardwoods and expertly fabricated by TGA Engineers.

Over 60, parallel-laminated (PLT) MASSLAM panels, each four metres long, were engineered from Australian hardwood and installed as part of an inverted flooring system. Providing exceptional strength, warmth and texture, with an exposed timber finish throughout the three-storey interior.

In addition, glue-laminated hardwood beams and columns, ranging from 3.5m to 3.9m in length, define the reconstructed post-and-beam structure. The heritage-listed building is crowned with a spectacular angled roof of taper-cut MASSLAM rafters, reaching upwards to a vast skylight that floods the space with natural light and showcases the architectural beauty of timber.

After six years of detailed planning, design and restoration, The Boot Factory reopened in 2024 as a vibrant civic and innovation hub. Inside are multi-purpose, flexible community spaces, a café, seniors centre and revitalised courtyard. It deserves to be celebrated as a prime example of how Australian timber can revitalise heritage buildings with sustainable, design-led results.

The Boot Factory wasn’t the only MASSLAM project to celebrate success. Bradfield’s First Building of the Advanced Manufacturing Readiness Facility (AMRF), designed by Hassell in collaboration with Djinjama, won the Sustainability – Excellence in Timber Design category at the 2025 TDA’s.

Adopting a circular economy approach to construction, every element of the First Building was carefully designed with future reuse in mind. Central to this strategy was the use of MASSLAM glue-laminated beams (mezzanine and roof) and column infills with a total of 475m3 of MASSLAM featured throughout.

During the earliest conceptual stages of AMRF, Hassell joined ASH to explore how Australian mass timber could be designed for maximum efficiency. By embracing timber’s natural structural advantages from the outset, the team unlocked smarter, more cost-effective solutions, whilst ensuring seamless Design for Manufacture and Assembly (DfMA) outcomes.

As the only Australian mass timber supplier trustworthy of delivering both the size and volume of locally sourced hardwood required for this project, ASH’s MASSLAM was integral to achieving the project’s sustainability goals.

A deserving winner of the sustainability award, the First Building’s credentials are exemplified further by its expansive 1,300 square metre green roof, alongside a 180kW solar panel system and 460kWh battery, supplying clean, renewable energy to the building.

Rainwater harvesting adds another layer of efficiency, with run off collected from the roof into a 150kL in-ground tank. This water is treated and used for landscape irrigation and grey water applications such as the building’s toilets.

More than 14,000 native plants bring the “green” roof to life, supporting local biodiversity and reducing roof temperatures by up to 20 degrees.

View full image gallery and read our project feature on AMRF’s First Building.

Located in Barton, ACT, 23 National Circuit was also recognised as a finalist in two Australian Timber Design Award categories for 2025; Excellence in Timber Design (Commercial Buildings) and Excellence in the use of Timber Products (Australian Certified Timber).

Designed by Stewart Architecture and build by DOMA Group, 23 National Circuit was one of the first mass timber buildings in Canberra. With sustainability and occupant wellbeing prioritised, glue laminated MASSLAM beams and columns were used throughout the project.

Australian Sustainable Hardwoods (ASH) is proud to have contributed to each of these award-winning timber projects and congratulates all who contributed to bringing these exceptional buildings to life.

Together they demonstrate how Australian-made mass timber can deliver exceptional performance, beauty and tangible sustainability results, all while supporting local jobs and industries.

For architects and builders, MASSLAM represents a new era of construction.

"*" indicates required fields