Some of the avoidable issues we come across after customers take home their laminated timber benchtops, shelves or panels are end splits or cupping. We’ll outline why these issues occur, but better yet, we’ll give you simple advice and tips to prevent these issues occurring in the first place.

Cupping in evenly kiln dried, laminated timber products is the result of one side being exposed to larger moisture variations than the other. Cupping is not a fault of a solid timber product, it is a result of poor storage and handling.

It is imperative that after purchasing a laminated timber panel, like a benchtop, it is stored flat off the ground, protected from the weather, wind and direct heat and not exposed to extreme changes in humidity. ASH laminated panels are fully wrapped in protective plastic and they should remain fully wrapped or resealed after opening until they are ready to be installed/machined/coated.

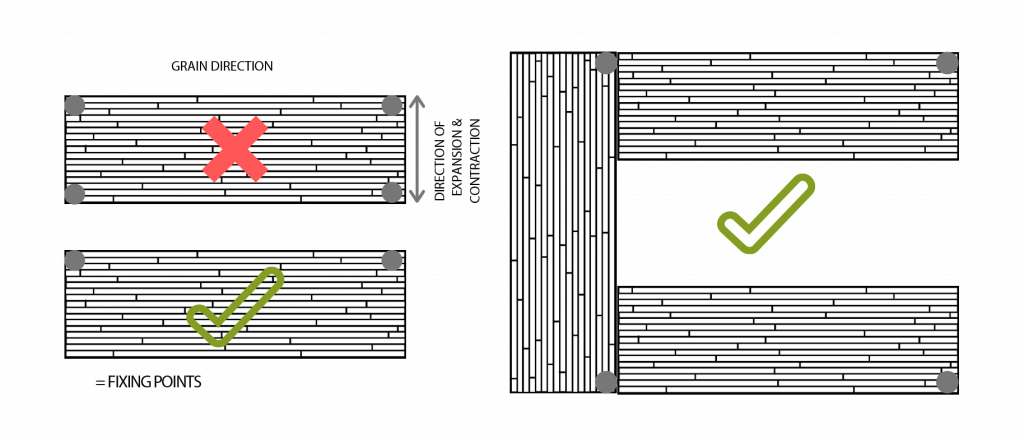

It is important to understand that timber naturally expands and contracts with variations to atmospheric conditions (e.g. temperature and humidity) and most importantly, wood moves in width and thickness, not length. This is an ordinary characteristic of timber that you will find in any solid wood products sold anywhere.

End splitting is the result of moisture content changes which are more rapid at the exposed end grain of timber. The stress created by this movement can result in splitting at the end.

Splitting in timber sometimes occurs between rigid mechanical fixings. If a laminated panel, (particularly a wide panel), is restrained by multiple mechanical fixings across the width, as a panel contracts to equalise with its environment, the contraction is limited to between rigid fixings. If the panel is not given the ability to contract evenly across the entire width, a split can occur between the rigid fixings.

A preventative measure is to coat the product such that moisture is slowed/prevented from leaving the panel, and fix the panel such that you allow it to expand and contract.

The best solution to timber splitting and cupping is to prevent it in the first place. It is recommended the following steps be taken to preserve the quality and stability of your high value, appearance grade, ASH laminated products:

When fixing, make an oversized or elongated hole in the cross rail. Make sure your holes are big enough and that your screws are placed in the holes so that the top has room to shrink.

Should your product have suffered cupping or splitting, here are some troubleshooting tips if preventative measures weren’t adequate:

Timber cupping and splitting are both issues that are completely avoidable. The main aim when working with laminated timber products is to seal, fix and protect your timber products so that it allows the timber to expand and contract naturally. The prevention, where possible, of any moisture changes wherever you are storing or installing your products will help avoid issues.

"*" indicates required fields