We sometimes get asked the question “why has my hardwood panel split?” or “my timber benchtop is cupping, what do I do?” and the answer is generally quite simple. However, this blog isn’t here to give you just answers, it’s purpose is to give you advice so that you can prevent any splitting or cupping to begin with.

Cupping is the result of one side being exposed to larger moisture variations than the other. ‘Cupping’ is not a fault of a solid timber product. It is a result of storage and handling. It is imperative that after purchasing your benchtop you store it flat, protected from the weather, wind and direct heat and not exposed to extreme changes in humidity. The panels are to be full wrapped in plastic until it is required.

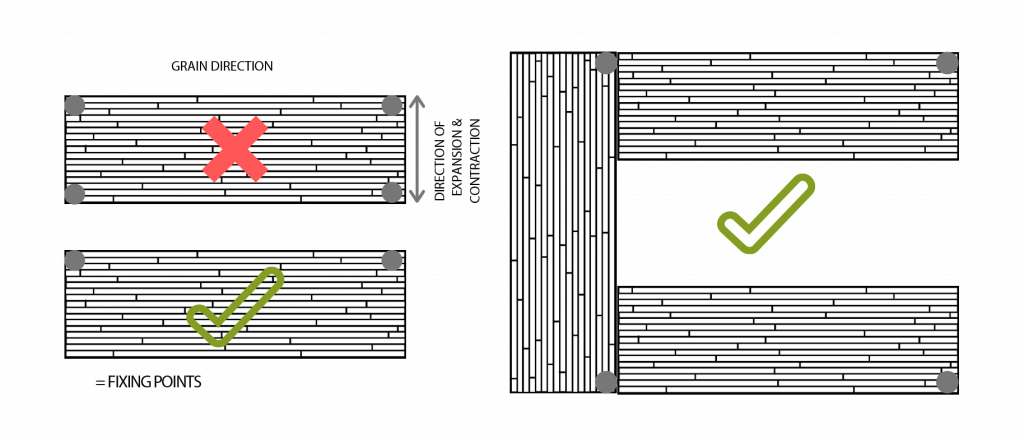

It is important to understand that timber naturally expands and contracts with variations to atmospheric conditions (e.g. temperature and humidity) and most importantly, wood moves in width and thickness, not length. This is an ordinary characteristic of timber that you will find in all solid wood products available.

End splitting is the result of moisture content changes which are more rapid at the exposed end grain of timber – the stress created by this movement can result in splitting. A preventative measure is to fix the panel so that you allow it to expand and contract.

Timber cupping and splitting are both issues that are completely avoidable. The main aim is to seal, fix or protect your timber products so that it allows the timber to expand and contract naturally or prevent any moisture changes.

Now on to the easy part: prevention.

To prevent your timber product from cupping, you must do one or all of the following:

When fixing, make an oversized or elongated hole in the cross rail. Make sure your holes are big enough and that your screws are placed in the holes so that the top has room to shrink.

Lastly, how to troubleshoot your timber product if you did not take the preventative measures above:

For more information and troubleshooting issues, read our full benchtop installation guide.

"*" indicates required fields